Actually JUST enough wiggle room to get them off as an assembly (after removing three of the bolts) which is just as well, because the last one is very solid.

Would probably need a vice to get it off, but it can stay on now.

Actually JUST enough wiggle room to get them off as an assembly (after removing three of the bolts) which is just as well, because the last one is very solid.

Would probably need a vice to get it off, but it can stay on now.

Must be an American poster.

I dunno what it is with Americans and ratchet abuse, but its a big thing on’t tube.

I dont use ratchets on stuck components, but I did once lend my ratchet to my GF’s dad who did, and I got it back in bits.

Ratchets are for undoing things quickly.

Unless you don’t have sufficient access to use anything else (which would be unusual) if you use one on a component that wont move, you are pointlessly putting a big load on a relatively delicate mechanism.

Its what breaker bars and T-bars are for.

I don’t really have a ratchet either. I have a few adjustable wrenches, that’s it. If it won’t come off with an adjustable wrench then it won’t be coming off no matter what anyways.

The end with the “spike” where you insert a pipe into, that pipe is called a “cheater bar” in the US. They are used on arbor presses as well.

I guess this is also why you don’t see spiked ends on ratchets, because they don’t want you using cheater bars with it.

Things like these do exist as well, did a good job too when I used one.

https://www.wtools.com.tw/products/torque-multiplier/

I have a few ratchets, and would like to keep them intact.

I hope you dont actually mean an adjustable crescent wrench above.

If you mean a Stilson, they will shift stuff, but they do tend to chew things up a bit.

I mention a spiked-ended ratchet commonly available in Taiwan up above somewhere. Can’t remember seeing it in The Yook

Not heard of them. Interesting.

Will probably be only “academic interest” though

“Each order has to reach US$10,000, otherwise we might need to add US$200 for the custom expense. Moreover, each item has to meet the minimum packing quantity to make it integral.”

Since the average tightening angle corresponding to 40 ft-lbs dry was 220 degrees (see graph up above…er…somewhere) I tightened the head bolts (with the threads lubricated with Permatex Aluminium antiseize) in 4X55 degree increments, recording the torque reached.

The first 2 torques, at 55 and 110 degrees, are “nominal”, since the wrench is almost unreadable at these low values. Not very precise at the higher values either, but I think some of that scatter is real.

Unsurprisingly, torque values reached lubricated are less than the dry specification.

Looking at the graph again, there seems to be a systematic increase in final torque across the tightening sequence, IOW from the centre to the outside of the head.

I suppose this may reflect a bowing of the head, and may not be a good sign.

If the HG pops it wouldnt necessarily invalidate the method, bu wouldnt give much confidence in it

And vice versa, of course.

If with a constant bolt tension across the head, as above, you get more torque at the ends, this seems to imply that a constant torque across the head wont give you a constant bolt tension, (and this may not be what you need, as I ve been assuming)

If ive got this the right way round, you”ll get, and may need, more tension in the middle.

Tricky

Actually, if you plot the final torques (at 220 degrees with aluslip) there is a suggestion that the first central diagonal pair of bolts tightened (front left to back right) may take the tension off for the next pair (front right to back left) and so reduce its torque, but beyond that there isn’t a clear pattern, so I’m not going to worry about it for now.

I just lost the timing belt tensioner spring, so I’ll worry about that instead.

I need to replace a lost cam sprocket bolt.

I’d guess I probably lost it when I was turning the car upside down looking for the tensioner spring that I apparently didn’t need (I now think I can tension that manually) ironic idiocy stylee.

The bolt appears to be unobtainium as a specific car part, but its, like, a bolt, so there might be some hope of sourcing a high grade flange bolt and thick washer that would do the job.

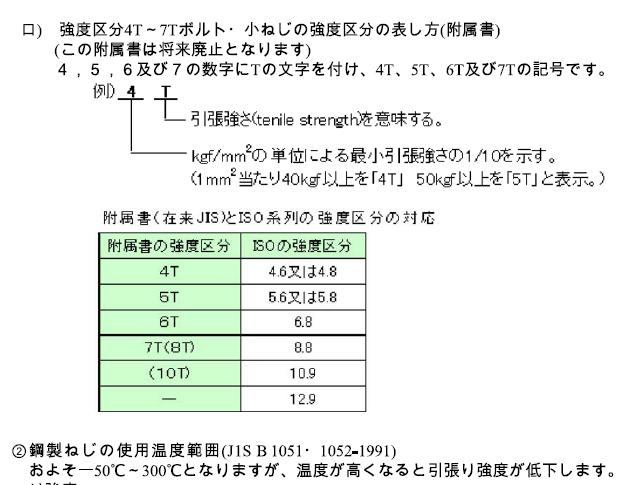

CB20 manual shows the torque range for 8mm diam 7T (apparently JIS or Japanese Industrial Standard, which is almost but not quite the same as ISO metric. Heads are smaller and they have their own tensile strength grades. But I HOPE and believe the threads are the same) bolts to be 14.5-21.7 ft lbs, whereas the cam bolt is 21.7-32.5. This seems to suggest that the cam bolt is some higher grade than those listed in the standard table, which only goes to 7T.

This table gives torque values for ISO metric bolts

https://www.fastenermart.com/files/metric_tighten_torques.pdf

For a fine M8 of Property Class (grade) 12.9 (the highest Metric Grade listed) tabulated torque is 33 ft lbs, the same as the specified upper limit torque for the cam bolt

.

After A LOT of poking around, I found this table of JIS and ISO metric strength equivalents

ttps://forums.ninja250.org/posting.php?mode=topicreview&t=88348&tro=1

JIS mark----------------------ISO metric mark

4 or 4T---------------------------4.6~4.8

5 or 5T---------------------------5.6~5.8

6 or 6T------------------------------6.8

7 or 7T------------------------------8.8

8 or 8T------------------------------8.8

10 or 10T--------------------------10.9

This suggests that 10T /10.9 may be the highest JIS grade. According to the above table, tabulated torque for an M8 fine thread 10.9 class bolt is only 28 ft-lb, less than that specified for the cam sprocket bolt, so if that is what it is, it seems it would be a bit marginal for the job.

This paper describes the development of high strength steels by Nippon Steel, and confirms that, post 1967 until their introduction in 1999, 10T was the highest grade available, due to concerns over hydrogen embrittlement and delayed fracture of higher strength steels.

(Any DIY job in Taiwan has the lurking potential to turn into an industrial archaeology thesis. I just want a bolt)

So, though uncertain as to what these bolts are, or could be, actually made of, best bet would seem to be to try and get an ISO metric 12.9 grade flange head bolt that’ll fit. I can perhaps take a silicone impression of the thread from the blind hole in the end of the camshaft.

I havn’t managed to lose the crank pulley bolt yet, which MAY be a larger version of the cam bolt (visually it looked like one as far as I can remember) with a flange on the head and a similarly super-thick washer.

I could take this around the bolt emporia as a pattern, though that might cause more confusion than its worth.

Trick is finding a good bolt boutique, a good trick if you can do it.

Or there is the Internyet

Don’t stress about screws or whatever.

There are screw shops all over Taiwan, I don’t know kaoshung or whatever but if one guy don’t have it, another will.

Also remember Taiwan used to be Japanese territory, JIS is not an alien concept to the Taiwanese as many, if not most industrial equipment or supplies are either from Japan or are of Japanese brand.

So nobody here is going to look at you like you’re from another planet if you need a JIS spec bolt. Best to take the original bolt you have and show it to the screw shop, they are sure to have something.

Now there might be different terminology and that I can’t help you…

I think I would actually want to check the engine for cracks in the casting after that time you lit a fire under it…

Does it even run at all?

I don’t think that’s the point any longer. It’s more like a Zen and the Art of Automobile Maintenance experience and the avoidance of gumption traps at this point.

Probably easier to just tow the thing to a scrap yard and sell it for scrap. Be sure to remove the license plate and take it to the DMV to report it as scrapped.

You will probably get about 20,000nt for the scrap metal in a car.

Cool. Though I think that might be an over estimate, a 5K profit over the period of ownership.

We don’ need no steenkeeng depreciation.

Now think for a moment…

…and then tell me how you think I might go about determining that.

HINT: The method might require something to hold the camshaft sprocket on, among other things

Meanwhile, back on (in?) the Zen…

I THINK the original is likely to have been JIS, but I might be able to replace with ISO metric, which is available in stronger grades (as above).

I took an RTV impression of the blind hole in the end of the camshaft, using half a small tongue depressor. This worked quite well, Threaded section is 20mm long, with the last 6mm of the hole unthreaded, which is useful to know.

Using that impression, I found a 10mm bolt (I miss measured the hole as 8mm, The extra thickness ameliorates the concern over strength) that threads in. Wrong length, with a shank (THINK the original was all threaded), and markings that I can’t interpret, but I can use it as a pattern when bolt-buying .

Well, this is embarrassing.

After dragging inside the sills with a magnet, found the original. Safe place syndrome.

Bolt head has two pips in line. According to this Toyota repair manual (I assume the bolt isnt manufacturer-specific)

supras.org.nz/techinfo/TSRM/25_B.pdf

thats a JIS 6T , equivalent to ISO metric 6.8.

That strength class isn’t in the torque table above. Perhaps one is supposed to interpolate?

www.metric-bolt-torque.com/metric-thread/metric-th…/

has it as 27 ft-lbs. That table is coarse thread only, and they can’t spell strength. but on paper, as suspected, the original bolt looks to be under-strength for its specified torque.

I’m going to use it anyway, because

(a) its the original, and I get enough “you think you know more than the manufacturer” flak as it is

(b) there isn’t clearance to get my torque wrench on it in situ anyway, so all this agonising over torque values is a bit moot.

Thought of improvising with my GF’s luggage scale, as per here

www.engineeringtoolbox.com/torque-wrench-luggage-s…l

but the luggage scale, being digital, is bust.

I should perhaps have torqued it before I put the head back on, but I’m not taking the head off again for this

Torque is overrated anyway.